Company News

Ask This Question Before Hiring a Company for IR Inspections

Is the person performing your thermal imaging/IR inspections qualified and able to provide you the accurate and detailed results you expect? At Heat Seeking Thermal Imaging, my technicians and I are very passionate about the great value our services provide our clients. We take great pride in the work we do and want to ensure…

Read MoreObtaining GasFind IR Fugitive Emissions Inspections in the Winter

As the winter months are upon us for many areas of North America, it’s often thought that this time of year is not effective for GasFind IR fugitive emissions inspections due to the cold weather. In fact, this isn’t true. GasFind IR fugitive emissions inspections can be as effective in the winter as it is…

Read MoreMake Infrared Electrical Inspections Part of Your Preventative Maintenance Plan

Infrared electrical inspections can be done in a variety of industries to find problems before they arise. Including infrared electrical inspections in your preventative maintenance plan can reduce downtime and electrical equipment damage and help you pinpoint potential problems before they cause a larger issue. Infrared electrical inspections should be conducted annually in order to…

Read MoreHow do Thermal Cameras Work and When Should They Be Used?

At Heat Seeking Thermal Imaging, we use thermal cameras in a number of applications. From electrical and mechanical surveys to utility substations, thermal cameras help in the discovery of building problems not always visible to the naked eye. We’re often asked, how do thermal cameras work? And what applications should they be used in? This…

Read MorePreparing for a Thermographic Building Inspection

Thermographic Building inspections serve many purposes and can help property owners identify a variety of issues in and around the home. Typical thermographic Building inspections include: Energy efficiency inspections Moisture intrusion inspections Electrical safety inspections Structural defect inspects Installation issues What are infrared thermographic Building inspections? Infrared thermographic Building inspections involve the use…

Read MoreGas Leak Detection Using GasFind IR Technology

The measurement of industrial gases and chemical compounds that are invisible to the naked eye on a daily basis. Gas leak detection needs to be a top priority companies. With a product that is invisible, companies need access to the technology necessary to detect leaks. Heat Seeking Thermal Imaging uses GasFind IR technology to spot…

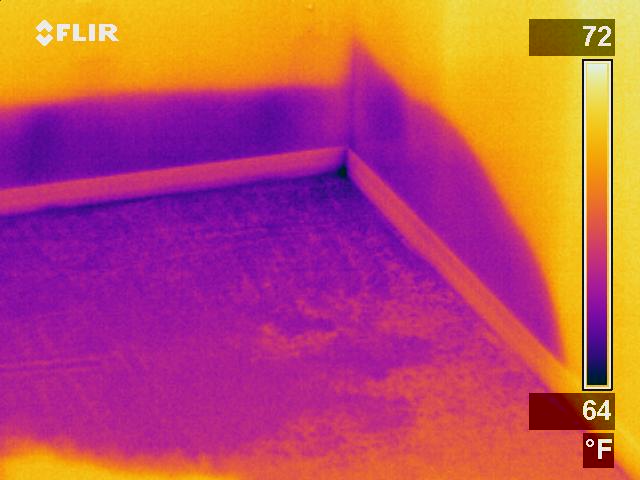

Read MoreInfrared Roof Inspections Help Detect Moisture Intrusions

As the days get shorter and the air gets colder and natural moisture is more common, it’s time to consider infrared inspections to help detect potential roof moisture instructions. Heat Seeking Thermal Imaging recommends getting infrared roof inspections to catch any moisture intrusions, or structural hazards. There are certain criteria that need to be met…

Read MoreDetecting Electrical Hazards with Electrical Thermal Imaging

Electrical thermal imaging inspections can help detect electrical issues and hazards and prevent an eventual catastrophe. Electrical thermal imaging is one of the tools used to acquire data to enable us to produce and provide an informative report, which will assist the client in directing a precise and accurate repair to the issue. By hiring…

Read MoreCost savings in predictor preventative maintenance programs

In times of economic uncertainty and the cutbacks in which we are experiencing and seeing in many different industries and government sectors There’s often a lot of money that can be saved by spending a little money in the form of predict a preventative maintenance. This type of service and mindset will allow you to…

Read MoreA well ran PdM program

A well ran PdM program should consist of several thing 1) A Plan 2) Execution 3) Prioritization 4) Mitigation of issues found. Recommended actions should include oil analysis, vibration, ultrasonic and thermography routes and techs in place so that base lines can be established as soon as possible. The PdM program will be important to…

Read More